Nut bonding fastener heavy duty

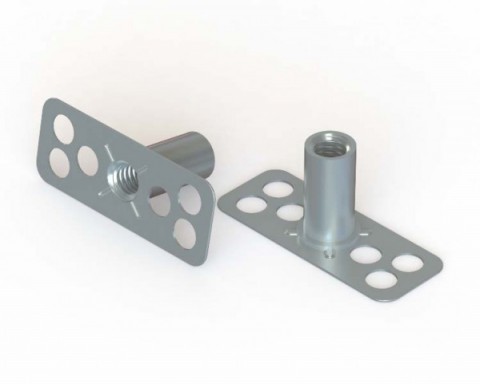

Nut Bonding Fastener Heavy Duty – Master-Plate® DFCY / DFPY

The heavy-duty nut bonding fastener Master-Plate® DFCY / DFPY is the ideal solution for secure, blind fastening of flanged nuts (M4–M6) to adhesive-compatible materials — without any drilling needed. The nut is welded onto a non-perforated base plate in zinc-plated steel or stainless steel 316L, creating a strong, durable threaded anchor when used with the correct adhesive.

Description

Available Versions

-

Thread sizes: M4 up to M6

-

Base plate diameters: 19 mm up to 58 mm

-

Material options: Zinc-plated steel or stainless steel 316L

-

Variants:

• DFCY – flanged nut welded on non-perforated base plate

• DFPY – flanged-head nut welded on non-perforated base plate for improved torque resistance -

Robust welding ensures high shear and torque resistance once bonded

Because of the non-perforated base plate and flanged nut design, the fastener delivers excellent torque resistance and cost-efficient installation when a suitable structural adhesive is used.

Why Choose Bonding Over Drilling?

-

No need for drilling — ideal for composites, plastics, metals, sandwich panels, and delicate substrates.

-

Avoids weakening of the substrate and reduces risk of leaks, cold bridges or corrosion — especially when using stainless steel.

-

Adhesive bonding distributes load evenly across the bonding area, instead of concentrating stress at discrete points as with mechanical fasteners.

-

Cleaner, smoother finishes and design flexibility — no visible holes or rivets, suitable for aesthetic or sealed applications.

-

Lighter overall construction: adhesives eliminate the need for heavy hardware — beneficial in weight-sensitive industries.

Installation & Adhesive Recommendations

-

Prepare the substrate surface thoroughly: clean, degrease, and — if required — abrade or prime according to adhesive specifications.

-

Select a structural adhesive suited to the substrate, environment (temperature, humidity, chemicals) and load requirements.

-

Apply the adhesive evenly and press the nut bonding fastener onto the surface so the base plate lies flat.

-

Allow adequate curing time per adhesive manufacturer’s instructions before applying load or torque.

For applications with heavy loads or exposure to vibration or harsh conditions, we recommend preliminary bond testing.

Typical Applications & Advantages

-

Fastening on composites, plastics, metals, wood, natural stone, glass, sandwich panels — where traditional drilling is undesirable or impossible.

-

Ideal for industries such as furniture, construction, transport, marine, aerospace: wherever a clean finish, lightweight construction or high strength-to-weight ratio is required.

-

Provides strong, corrosion-resistant threaded anchors without damaging the substrate — perfect for thin, sensitive or composite materials.

Download PDF

master_plate_perforated_drp_dfp_drc_dfc.pdfFrequently asked questions about Nut bonding fastener heavy duty

How strong is the bond?

Strength depends on the adhesive, the substrate, surface preparation, and bonding area. Correct surface prep is essential and testing is advized. The factory can test if samples are provided in Italy.

Can they handle vibrations?

With the right adhesive applied in the rigth circumstances, bonded fasteners can perform well under vibration loads.

Which adhesives are recommended?

Usually structural adhesives like epoxy, methacrylate or polyurethane. Give us more info about the application and in cooperation with a adhesive manufacturer, we can provide specific adhesive guidelines.

What materials can they be bonded to?

They are typically used on composites, plastics, metal panels, honeycomb structures, carbon fiber, and thin sheet materials.

Are the bonding fasteners always on stock?

For the best-selling items, of course, yes. For the other dimensions, the individual stainless steel components are very often in stock at the factory and only still need to be welded, so you should count on a minimum quantity of 200 pieces and a delivery time of 3 to 4 weeks. For the zinc-plated steel versions, the minimum quantity is 500 pieces due to the galvanizing process, which results in a longer delivery time of 5 to 6 weeks.

When is the non-perforated base plate type interesting?

In general, it can be stated that for medium-sized and large series, the non-perforated bonding fasteners are often more interesting, as on the one hand you save on average 72% of adhesive and on the other hand the quality of the bonded joint is improved.

The bonding quality is then much less dependent on the individual operator.

The shear strength is also higher than with the perforated version.

We recommend checking stock availability, as these items are often not on stock.