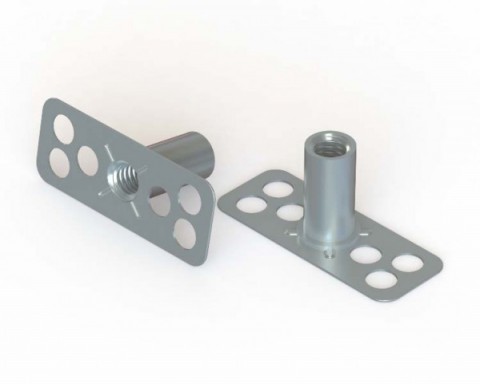

Insulation pin bonding fastener

Insulation Pin Bonding Fastener for Structural Panel Assembly and Thermal Insulation Applications

Overview – Adhesive-Bonded Fastening Solution for B2B Manufacturing

The Master-Plate® insulation pin bonding fastener delivers a no-drill, adhesive bonded fastening system for industrial assembly of insulation panels, composite panels, metal and plastic substrates. Designed for structural bonding without mechanical damage or thermal bridges, it supports engineers and buyers in aerospace, transport, construction and industrial manufacturing with high-quality stainless steel fasteners and precision dimensions.

Description

Features and Technical Specifications – Materials, Sizes, Tolerances, Configurations

• Product Types – CR (perforated base plate) and CRY (non-perforated base plate) insulation pin options allow flexibility in adhesive flow and bond strength.

• Base Plate Sizes – Available in 38mm version and tailormade possible from 15X15mm, 32X32mm to 58 mm square to match varied surface areas and load distributions.

• Pin Lengths – 50 mm to 100 mm nail length options to suit insulation thickness and panel depth requirements.

• Material Grades – Standard stainless steel AISI 316 (SS316) for superior corrosion resistance and performance in chemically aggressive environments; also available in steel zinc-plated versions.

• Clip & Cap Accessories – Supplied with AISI 316 38 mm round spring clip FAD03T38.51 and optional EPDM protective cap EE109-500 to cover sharp edges post-installation.

Industrial Bonding and Installation – Adhesives and Surface Prep

Selecting the correct structural adhesive such as epoxy or methacrylate systems is critical for achieving optimal lap shear and tensile strength in bonded joints and ensuring durability across temperature and humidity variations. In consultation with an adhesive specialist, we can recommend and supply the most appropriate solution.

• Surface Preparation – Clean, de-greased and, if required, abrade substrates prior to adhesive application to maximize surface energy and bond reliability.

• Bonding Benefits – Adhesive bonded fasteners reduce drilling, eliminate thermal bridging and maintain material integrity, particularly for thin composites, honeycomb core panels, carbon fiber and plastics.

Common Applications – B2B Use Cases in Industrial Assembly

• Thermal insulation fixing on concrete, metal panels, sandwich structures, HVAC duct insulation, composite panels.

• Bonded fastening where mechanical drilling is unsuitable due to risk of substrate damage or leak paths.

• Attachment solutions for transportation interiors (rail, aero), prefab construction elements, marine composites.

Quality Assurance – Stock, Lead Times, Minimum Orders

Standard best-selling items are maintained in stock; custom sizes require minimum quantities (e.g., 200 pieces for SS316 fasteners, 500 pieces for zinc plated versions) with longer lead times due to galvanizing processes.

Why Choose Adhesive Bonded Insulation Pins

• No drilling or weakening of materials.

• Compatible with structural adhesives for load-bearing performance.

• Ideal for composite bonding and panel assembly across multiple B2B industries.

Download PDF

master_plate_quilting_pins_cr_cry.pdfFrequently asked questions about Insulation pin bonding fastener

How strong is the bond?

Strength depends on the adhesive, the substrate, surface preparation, and bonding area. Correct surface prep is essential and testing is advized. The factory can test if samples are provided in Italy.

Can they handle vibrations?

With the right adhesive applied in the rigth circumstances, bonded fasteners can perform well under vibration loads.

What materials can they be bonded to?

They are typically used on composites, plastics, metal panels, honeycomb structures, carbon fiber, and thin sheet materials.

Which adhesives are recommended?

Usually structural adhesives like epoxy, methacrylate or polyurethane. Give us more info about the application and in cooperation with a adhesive manufacturer, we can provide specific adhesive guidelines.

Are the bonding fasteners always on stock?

For the best-selling items, of course, yes. For the other dimensions, the individual stainless steel components are very often in stock at the factory and only still need to be welded, so you should count on a minimum quantity of 200 pieces and a delivery time of 3 to 4 weeks. For the zinc-plated steel versions, the minimum quantity is 500 pieces due to the galvanizing process, which results in a longer delivery time of 5 to 6 weeks.