Bonding fastener

Our bonding fasteners offer reliable threaded connections for composite panels, sandwich structures, and insulation materials — without drilling or damaging the surface.

With over 28 years of experience, Juno Industries provides fastening solutions that combine strength, precision, and durability.

What Is a Bonding Fastener?

Definition and Working Principle

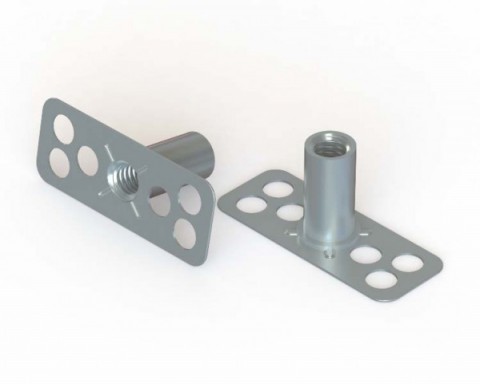

A bonding fastener is a metal insert with an internal or external thread, designed to be bonded to a surface using adhesive instead of being mechanically screwed in.

Its base (often perforated or structured) allows the adhesive to flow through and create a strong mechanical and chemical bond.

Available Types of Bonding Fasteners

-

Bonding studs / male fasteners

-

Bonding nuts / female fasteners (with or without perforations)

-

Bonding spacers and collars

-

Insulation pins and anchors

-

Custom-made bonding inserts

-

Optional accessories: mixing nozzles, adhesive dispensers, and epoxy kits

Why Choose a Bonding Fastener?

Main Advantages

-

No drilling, welding, or heat distortion

-

Perfect for lightweight composite or sandwich materials

-

Even stress distribution across the bonded area

-

Excellent resistance to vibration and corrosion (depending on material)

-

Quick installation and aesthetic surface finish

Typical Applications

-

Composite structures (fiberglass, carbon fiber, honeycomb)

-

Sandwich panels and insulation boards

-

Marine, automotive, aerospace, and construction industries

-

Areas where drilling or through-fixing is not possible

How to Select the Right Bonding Fastener

1. Internal Thread Size

Match the fastener to your bolt or threaded rod — typically M4 to M10 depending on the load and material thickness.

2. Base Design and Geometry

-

Perforated base: maximizes adhesive penetration and grip

-

Flat or domed base: depends on surface shape and adhesive volume

-

Height and diameter: adapt to the available bonding surface and load capacity

3. Material Choice

-

Stainless steel (A4 / 316): excellent corrosion resistance for marine or outdoor use

-

Zinc-plated steel: economical indoor applications

-

Brass: prevents galling when combined with stainless-steel screws

-

Custom alloys: available for specific environments (chemical or high-temperature)

Installation Guide – Step by Step

Surface Preparation

Clean, degrease, and lightly abrade the surface to improve adhesion. Ensure it is dry and free from dust or contaminants.

Bonding Process

-

Select a suitable two-component or epoxy adhesive.

-

Apply adhesive evenly under and through the fastener base.

-

Position the bonding fastener carefully and press firmly.

-

Allow the adhesive to cure fully before applying any load.

Quality Check

After curing, check alignment and bonding strength before tightening bolts or screws.

Benefits of Juno Industries Bonding Fasteners

Key Strengths

-

High-quality materials and precision manufacturing

-

Reliable load capacity even in thin or soft materials

-

Large product range (studs, nuts, collars, custom inserts)

-

Technical advice tailored to your application

-

Fast delivery across Europe

Added Services

-

Free samples for testing and validation

-

Low minimum order quantities (100 pcs standard, 50 pcs for M10+)

-

Technical support for adhesive selection and installation

Frequently asked questions about Bonding fastener

When is the non-perforated base plate type interesting?

In general, it can be stated that for medium-sized and large series, the non-perforated bonding fasteners are often more interesting, as on the one hand you save on average 72% of adhesive and on the other hand the quality of the bonded joint is improved.

The bonding quality is then much less dependent on the individual operator.

The shear strength is also higher than with the perforated version.

We recommend checking stock availability, as these items are often not on stock.

Are the bonding fasteners always on stock?

For the best-selling items, of course, yes. For the other dimensions, the individual stainless steel components are very often in stock at the factory and only still need to be welded, so you should count on a minimum quantity of 200 pieces and a delivery time of 3 to 4 weeks. For the zinc-plated steel versions, the minimum quantity is 500 pieces due to the galvanizing process, which results in a longer delivery time of 5 to 6 weeks.