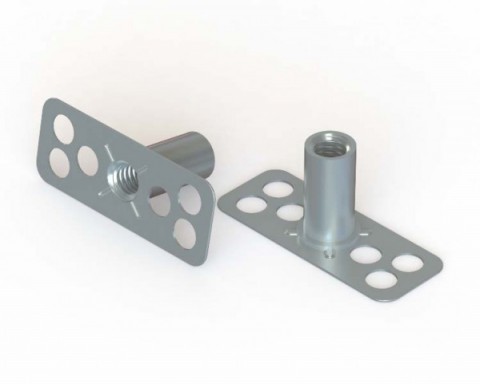

Male stud bonding fastener heavy duty

High-Strength Bonding Stud Master-Plate® PRS – Reliable Blind Fastening Without Drilling

Description

Specifications of the High-Strength Bonding Stud

The Master-Plate® PRS is engineered for applications requiring maximum tensile strength and durable adhesive bonding.

-

Available with perforated base plates from 19 mm to 58 mm.

-

Threaded studs from M5 to M10.

-

Countersunk head ensures a stronger welded connection to the base plate.

-

Length options: 45, 50, 60, 70, 80, 90, and 100 mm.

-

Materials: white zinc-plated steel or stainless steel 316.

When the Master-Plate® PRS is pressed onto the applied adhesive, the glue seeps through the perforations, forming a strong mechanical bond that provides a higher tightening torque capacity.

How to Fasten Without Drilling?

Bonding instead of drilling for greater design flexibility

A bonded insert is designed to be attached to composite, metal, or plastic surfaces without the need for drilling holes.

The Master-Plate® range includes a variety of bondable studs, nuts, spacers, and adhesive cable tie mounts, enabling quick and clean fastening of cables and hoses.

Benefits of fastening without drilling:

-

No risk of leakage or material weakening.

-

No galvanic corrosion thanks to stainless steel 316.

-

No mechanical stress on the substrate.

-

Quick installation and maximum design freedom for engineers and designers.

Need Advice on the Ideal Adhesive?

Feel free to contact Juno Industries for expert guidance on the most suitable adhesive for your specific application.

We work closely with leading adhesive specialists to ensure optimal bonding strength and performance for every project.

Download PDF

master_plate_high_perf_prs_prsy.pdfFrequently asked questions about Male stud bonding fastener heavy duty

How strong is the bond?

Strength depends on the adhesive, the substrate, surface preparation, and bonding area. Correct surface prep is essential and testing is advized. The factory can test if samples are provided in Italy.

Can they handle vibrations?

With the right adhesive applied in the rigth circumstances, bonded fasteners can perform well under vibration loads.

Which adhesives are recommended?

Usually structural adhesives like epoxy, methacrylate or polyurethane. Give us more info about the application and in cooperation with a adhesive manufacturer, we can provide specific adhesive guidelines.

What materials can they be bonded to?

They are typically used on composites, plastics, metal panels, honeycomb structures, carbon fiber, and thin sheet materials.

Are the bonding fasteners always on stock?

For the best-selling items, of course, yes. For the other dimensions, the individual stainless steel components are very often in stock at the factory and only still need to be welded, so you should count on a minimum quantity of 200 pieces and a delivery time of 3 to 4 weeks. For the zinc-plated steel versions, the minimum quantity is 500 pieces due to the galvanizing process, which results in a longer delivery time of 5 to 6 weeks.

When is the non-perforated base plate type interesting?

In general, it can be stated that for medium-sized and large series, the non-perforated bonding fasteners are often more interesting, as on the one hand you save on average 72% of adhesive and on the other hand the quality of the bonded joint is improved.

The bonding quality is then much less dependent on the individual operator.

The shear strength is also higher than with the perforated version.

We recommend checking stock availability, as these items are often not on stock.