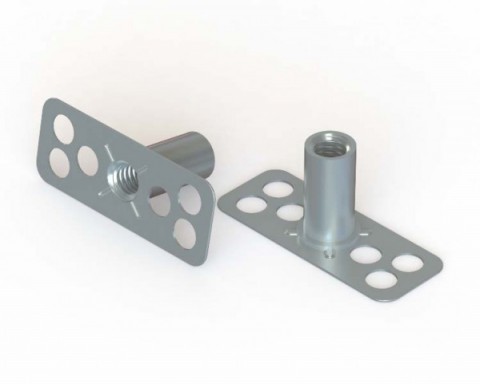

Tailormade bonding fasteners

As a preferred supplier of Specialinsert® in Italy, we dispose of various possible production processes such as cold forming, turning, laser cutting and welding of the parts, which means that we can offer special cost-effective solutions for small quantities.

Description

Minimum quantities depend on the sizes that are required but often start from 1.000 pieces.

For stainless steel parts you have the advantage that the delivery time will not be disadvantaged for an extra treatment.

How to attach without drilling?

An bonding fastener is designed to be attached to composite, metal, and plastic surfaces without the need for drilling holes. The standard range includes male stud bonding fasteners, nut bonding fastener, and bonding spacers of various types and sizes, as well as cable ties. This allows easy fastening of cables and hoses. Drilling is unnecessary because this method utilizes a base plate and adhesive. This reduces the potential for leaks as well as cold bridges. Additionally, there is no risk of galvanic corrosion, as they are available in stainless steel (ss316). The use of adhesive does not create tension in the material. Since they can be attached to any adhesive material, this offers design freedom.

Download PDF

master_plate_specials.pdfFrequently asked questions about Tailormade bonding fasteners

How strong is the bond?

Strength depends on the adhesive, the substrate, surface preparation, and bonding area. Correct surface prep is essential and testing is advized. The factory can test if samples are provided in Italy.

Can they handle vibrations?

With the right adhesive applied in the rigth circumstances, bonded fasteners can perform well under vibration loads.

What materials can they be bonded to?

They are typically used on composites, plastics, metal panels, honeycomb structures, carbon fiber, and thin sheet materials.

Which adhesives are recommended?

Usually structural adhesives like epoxy, methacrylate or polyurethane. Give us more info about the application and in cooperation with a adhesive manufacturer, we can provide specific adhesive guidelines.