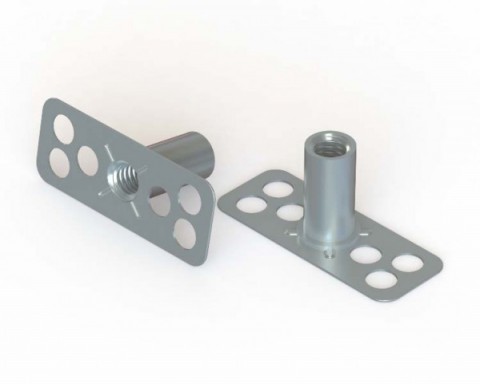

Male stud bonding fastener

Bonding Stud with Perforated Base Plate

Our adhesive bonded studs with perforated base plate provide a reliable and durable solution for creating strong mechanical connections in plastics, composites, and laminated materials. The perforated base plate allows the adhesive to bond optimally, ensuring firm integration of the insert into the substrate. Available from M4 up to M8 in steel zinc plated and stainless steel 316.

Description

What Are Bonding Studs with a Perforated Base Plate?

These fastening solutions consist of a metric stud that is permanently secured via a perforated base plate. During bonding, the adhesive flows through the perforations, creating an anchor capable of withstanding high tensile and shear forces.

Benefits of Perforated Bonding Fasteners?

Strong and Durable Connection

The perforated base plate ensures optimal adhesive distribution, resulting in very strong mechanical anchoring.

Ideal for Thin or Sensitive Materials

These bonding inserts prevent local deformation since no heat or mechanical load is applied, unlike welding or pressing.

Corrosion-Resistant Design

The bonding fasteners are also available in high-quality stainless steel 316 suitable for demanding environments such as automotive, marine, and industrial applications.

Applications of Bonding male Studs

Composite Panels and Sandwich Structures

For mounting components on composite panels where traditional fastening is not possible.

Plastic Housings

Creates a strong threaded connection without damaging the decorative material.

Interior and Exterior Components

Suitable for car interiors, machine enclosures, cabinet systems, and more.

Available Sizes and Configurations

Our perforated adhesive bonded inserts are available in various metric thread sizes, with different base plate diameters and lengths. Custom dimensions or special materials can be provided upon request.

Why Choose Juno Industries?

Specialized Expertise in Threaded Inserts

We offer expert guidance to help you select the right insert based on material and application.

European Stock and Fast Delivery

Our central location allows quick delivery to all EU countries.

Tailor-Made Solutions

From standard products to custom designs — we support your project from engineering to final assembly.

Contact and Technical Support

Do you need technical specifications, drawings, or advice for your project?

Our team is ready to assist with product selection, testing recommendations, and customized solutions.

Download PDF

master_plate_perforated_pr.pdfFrequently asked questions about Male stud bonding fastener

How strong is the bond?

Strength depends on the adhesive, the substrate, surface preparation, and bonding area. Correct surface prep is essential and testing is advized. The factory can test if samples are provided in Italy.

Can they handle vibrations?

With the right adhesive applied in the rigth circumstances, bonded fasteners can perform well under vibration loads.

What materials can they be bonded to?

They are typically used on composites, plastics, metal panels, honeycomb structures, carbon fiber, and thin sheet materials.

Which adhesives are recommended?

Usually structural adhesives like epoxy, methacrylate or polyurethane. Give us more info about the application and in cooperation with a adhesive manufacturer, we can provide specific adhesive guidelines.

Are the bonding fasteners always on stock?

For the best-selling items, of course, yes. For the other dimensions, the individual stainless steel components are very often in stock at the factory and only still need to be welded, so you should count on a minimum quantity of 200 pieces and a delivery time of 3 to 4 weeks. For the zinc-plated steel versions, the minimum quantity is 500 pieces due to the galvanizing process, which results in a longer delivery time of 5 to 6 weeks.

When is the non-perforated base plate type interesting?

In general, it can be stated that for medium-sized and large series, the non-perforated bonding fasteners are often more interesting, as on the one hand you save on average 72% of adhesive and on the other hand the quality of the bonded joint is improved.

The bonding quality is then much less dependent on the individual operator.

The shear strength is also higher than with the perforated version.

We recommend checking stock availability, as these items are often not on stock.