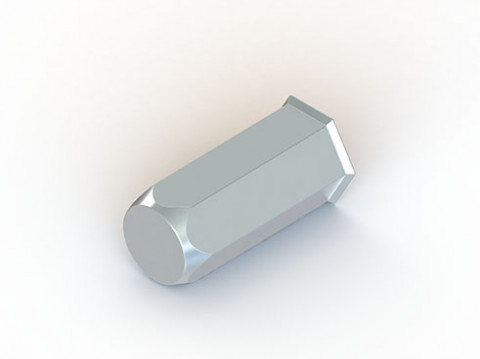

Semi hex self-locking rivet nut

Semi-hex Self-locking Rivet Nut – Deform-Nut® ETC/A & ETFM/A

What is a self-locking rivet nut?

The open semi-hex Deform-Nut® rivet nut with integrated thread-locking nylon ring — developed by Specialinsert® — gives you a secure internal thread in thin sheet metal, while preventing loosening under vibration.

It is available both in zinc-plated steel and stainless steel 304. Two head types are offered: flat head (ETC/A) and reduced-head (ETFM/A).

Installation is easy using a manual, electric or pneumatic rivet-nut tool: the nut deforms behind the sheet, forming a strong, vibration-resistant connection.

Description

Key Features

-

Suitable for sheet thickness from 0.5 mm up to 6.0 mm.

-

Material options: zinc-plated steel or stainless steel 304.

-

Semi-hexagonal body to resist rotation — preventing the nut from turning inside the sheet under torque or vibration.

-

Inner thread immediately usable after installation — no need for tapping.

-

Suitable for blind-side installation (one-sided access), ideal for profiles, enclosures or assemblies where backside is not accessible.

Advantages of Using This Rivet Nut

Reliable, reusable threaded connection

Once installed, it provides a robust internal thread.

Resistant to vibration and loosening

The self-locking nylon ring combined with the semi-hex body prevents loosening and rotation — perfect for environments exposed to vibration or dynamic loads.

Blind-side installation

Allows fastening where only one side of the sheet is accessible — useful for tubular profiles, closed sections or confined assemblies.

Simple and cost-effective assembly

Installation does not require welding or tapping — just a rivet-nut tool and a suitably drilled hole. Reduces labor, avoids heat or distortion, and works even on coated materials.

Recommended Use & Tips

-

Punch the correct hole according to thread size and sheet thickness.

-

Use a rivet-nut tool (manual, pneumatic or electric) to install. Screw the blind rivet nut onto the mandrel of the installation tool without touching the nylon ring.

-

Seat the nut so the head is flush with the sheet surface.

-

Tighten the screw through the self-locking ring — the connection is now set, vibration-resistant and ready for load.

-

For maximum security in vibrating or dynamic applications: verify grip range is correct and retighten if required.

When to Choose Steel vs Stainless Steel

-

Zinc-plated steel — suitable for general indoor applications or where corrosion risk is limited.

-

Stainless steel 304 — recommended for outdoor or where long-term durability is a requirement.

Download PDF

deform_nut_etca_etfma_tcazi_tfmazi.pdfFrequently asked questions about Semi hex self-locking rivet nut

Is the thread locking reusable?

The thread locking ensures retention only once, and then gradually decreases depending on the environmental conditions.