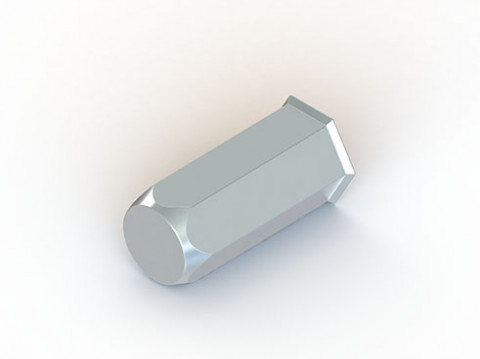

Cylindrical self-locking rivet nut

Cylindrical Self-locking Rivet Nut – Deform-Nut® TC/A/ZI & TFM/A/ZI

What is a cylindrical self-locking rivet nut?

A cylindrical self-locking rivet nut is a threaded insert designed to provide a strong internal thread in thin sheet material, even when only one side is accessible. During installation, the deformation zone clamps behind the sheet, while the integrated nylon locking ring prevents loosening due to vibration.

It is available in zinc-plated steel and stainless steel 304, with a choice of flat head or reduced head for applications with limited space.

Description

key features

-

Suitable for sheet thickness from 0.5 to 6.0 mm

-

Material options: zinc-plated steel or stainless steel 304

-

Two head types:

– Flat flange head (TC/A/ZI)

– Reduced head (TFM/A/ZI) for tight spaces -

Self-locking nylon ring for vibration-resistant performance

-

Blind-side installation — no rear access required

-

Ready-to-use internal thread immediately after installation

Why choose this rivet nut?

Blind-side installation for closed profiles and hollow structures

Ideal for tubes, box sections and assemblies where the rear side cannot be reached.

Strong internal thread

Provides a durable metal thread.

Maximum resistance against vibrations

The nylon locking ring keeps bolts and screws securely in place under dynamic loads and vibration.

Fast and cost-efficient mounting

No welding or tapping needed — simply drill, insert and set with a rivet-nut tool. Saves time and avoids heat distortion or coating damage.

Versatile in many applications

Perfect for enclosures, sheet-metal structures, machinery, metal cabinets, vehicles and general industrial fabrication.

Installation advice

-

Drill the hole according to the recommended diameter in the technical data sheet.

-

Use a rivet-nut tool (manual, pneumatic or electric) to install. Screw the blind rivet nut onto the mandrel of the installation tool without touching the nylon ring.

-

Seat the nut so the head is flush with the sheet surface.

-

Use a manual, electric or pneumatic rivet-nut tool to deform the backside and anchor the nut.

-

Install the screw or bolt into the internal thread — secure and vibration-resistant.

-

For dynamic applications: check torque after installation if needed.

Steel vs Stainless Steel — which to choose?

-

Stainless steel 304 → harsh environments & outdoor applications

-

Zinc-plated steel → cost-efficient for general indoor use and low-corrosion areas

Download PDF

deform_nut_tc_a_zi_tfm_a_zi.pdfFrequently asked questions about Cylindrical self-locking rivet nut

Is the thread locking reusable?

The thread locking ensures retention only once, and then gradually decreases depending on the environmental conditions.