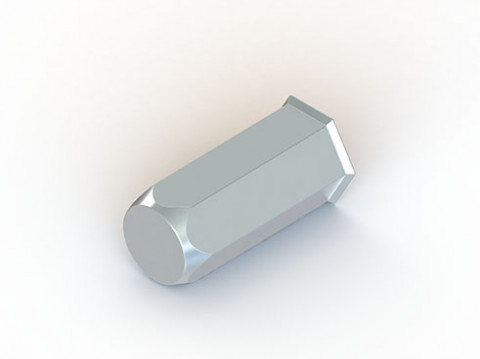

Manual tool for rivet nut

Manual Rivet Nut Installation Tool – Industrial Rivet Nut Setting Tool for B2B

Professional Manual Tool for Blind Rivet Nut Installation in Industrial Assembly

The manual rivet nut installation tool supplied by Juno Industries is a high-quality manual setting tool designed for B2B industrial applications, including blind rivet nut installation, threaded insert assembly, and maintenance of mechanical fasteners in sheet metal, structural components, and engineered assemblies. This industrial rivet nut setting tool supports a range of metric rivet nuts (M4 to M10) and is compatible with heavy-duty threaded inserts used in automotive, aerospace, and manufacturing sectors.

Description

Technical Specifications & Industrial Fastener Compatibility

Our manual tool for rivet nuts is constructed from reinforced alloy components to withstand repeated use in production and workshop environments. It is suitable for standard metric blind rivet nuts, including steel zink plated, stainless steel A2. The tool ensures precise deformation and correct expansion of the rivet nut behind the substrate for secure fastening.

Supported Rivet Nut Sizes and Thread Tolerances

• Compatible with metric blind rivet nut sizes M4, M5, M6, M8, and M10 industrial threaded inserts.

• Designed for ISO metric thread tolerances to guarantee consistent performance in demanding B2B manufacturing operations.

• Single tool enables fast setup for multiple rivet nut diameters with interchangeable screw reduction adaptors.

• Meets industry standards for mechanical fastening solutions and threaded insert installation tools in heavy-duty production.

Operating Instructions for Manual Rivet Nut Tool

Follow these rivet nut installation instructions to ensure safe and reliable setting of blind rivet nuts:

– Before using the tool, verify that the fitted equipment is suitable for the rivet nut to be applied.

– With the levers open, ensure that the screw protrudes from the head of the tool with a minimum length equal to the total length of the rivet nut. This is adjusted by turning the tool cover; no other adjustments are required.

– Insert the rivet nut onto the screw by rotating the knurled knob clockwise located at the back of the tool.

– Place the blind rivet nut into the drilled or punched hole.

– Tighten the levers to deform the rivet nut; ensure complete closure for optimal setting.

– Warning: force and fastening level must be tuned by the operator. Fully closing the levers helps reduce stress on the tool and ensures secure install.

– Check that the rivet nut is correctly deformed behind the thin surface and does not rotate.

– Remove the tool from the insert by turning the knurled knob on the back of the tool.

Instructions to Change Set-Up for Metric Thread Sizes (A8/K_ _M)

Follow these steps to change the thread size configuration of the manual rivet nut tool:

– Remove the tool cover and head assembly from the tool body; replace with a new head of the appropriate size by unscrewing it from the cover.

– Open the levers while blocking the driving pin; remove the current screw reduction adaptor.

– Select the screw reduction adaptor of the required size; screw it onto the driving pin, ensuring the hexagon socket of the screw mates with the conical rod. Tighten all components securely.

– Warning: the same screw reduction adaptor is used for both M8 and M10 sizes.

– Reattach the cover assembly and head to the tool body.

– We recommend applying a few drops of light oil on the tool screws and moving components to facilitate smooth rivet nut assembly and prolong tool life.

Industrial Applications & B2B Benefits

The manual rivet nut installation tool is ideal for:

• Vehicle body workshops, and sheet metal fabrication plants.

• Maintenance and repair operations (MRO) requiring installation of blind rivet nuts in structural panels.

• Threaded insert installation for mechanical fastening in steel, aluminum, and composite assemblies.

Additional Support, Samples & Technical Documentation

Juno Industries provides technical support, downloadable PDF datasheets, and sample requests to help you choose the correct rivet nut installation configuration. Contact our B2B support team for detailed product guidance.

Frequently asked questions about Manual tool for rivet nut

Which blind rivet nut should be used for thicknesses > 5 mm?

For thicker sheets and panels, it is best to use a rubber blind rivet nut, a TC/INT model, or a Flower-Nut. Each has different advantages, and the Flower-Nut is also available in stainless steel 316.