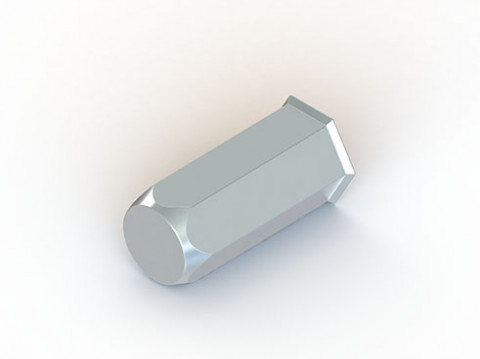

Insert for sandwich panel

Overview & Applications

What is this Threaded Insert for Sandwich Panel?

The TC/SC/1 threaded insert by Juno Industries is a high-performance solution for sandwich panels ranging in thickness from 10 mm up to 80 mm.

It bridges the gap between costly potted inserts and standard rivet nuts, offering mechanical anchoring plus adhesive bonding for durable inner threads.

Ideal Use-Cases & Industries

This insert is designed for applications where sandwich panels (e.g., honeycomb core or composite core) are used in: façades, building cladding, transport interior panels, industrial panels and structural composite elements.

It’s particularly effective when access to both sides of the panel is limited — a “blind” installation scenario.

Description

Technical Features & Benefits

Dual-Fastening Mechanism

The TC/SC insert features two parts:

-

A rivet nut that anchors into the top skin of the sandwich panel.

-

A blind grub screw (or adjusting insert) that is screwed until it reaches the bottom skin (and adhesive) of the panel core.

This combination prevents the insert from flipping or pulling out, delivering superior load resistance.

Material & Size Specifications

Available in thread sizes M6 & M8, in steel zinc-plated and stainless steel (303 SS) materials.

Engineered for skin (top layer) thickness from 0.5 mm up to 6.5 mm.

Supports panel core thicknesses (sandwich panel total) of 10-80 mm.

Strength & Performance Advantages

Compared to standard rivet nuts which rely only on skin-core bonding, this system provides mechanical anchoring + adhesive bonding, improving load-bearing capacity — especially in hollow or composite panels.

Because of this robust engineering, you avoid more expensive solutions like full resin potting or bonded bushes.

Installation Guide

Step-by-Step

-

Drill the correct diameter blind hole from one side of the sandwich panel.

-

Insert the rivet nut into the hole and set it using standard rivet-nut tooling so it anchors the top skin.

-

Inject structural adhesive into the rivet nut cavity, filling towards the panel core.

-

Screw in the adjusting insert/grub screw until it contacts the bottom skin or core adhesive layer.

-

Allow adhesive to cure fully (as per adhesive manufacturer). Once cured, the fastener is ready for use.

Best-Practice Tips

-

Ensure hole preparation and cleaning (e.g., degreasing) before installation to optimise adhesive bond.

-

Select adhesive compatible with panel core material and skin material.

-

Account for panel thickness variation and tolerance when choosing insert length/design.

Why Choose Juno Industries’ Insert for Sandwich Panel?

-

Combines mechanical and adhesive anchoring for greater reliability in sandwich panels.

-

Flexible across a wide range of panel types, thicknesses and core materials (honeycomb, composite, resin-based) – consistent with leading systems such as the patented Deform-Nut series.

-

Simplifies installation compared to more complex embedded or potted solutions — saving labour time and cost.

-

High quality materials available (steel zinc-plated, SS303) — tailored to your application environment.