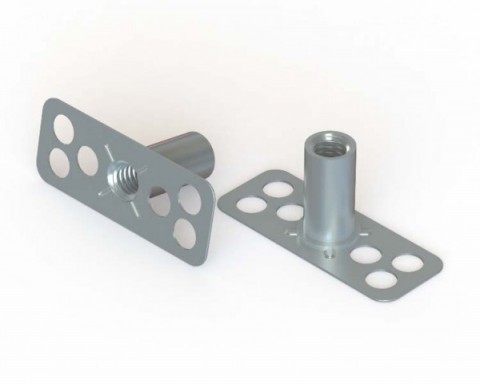

Insulation pin bonding fastener

Master-Plate® Insulation Pin Bonding Fastener – Adhesive Bonded Industrial Insulation Fasteners B2B

The Master-Plate® Insulation Pin Bonding Fastener is a high-performance, adhesive bonded insulation fastening solution for industrial and commercial applications. Engineered for no-drill assembly of insulation panels, composite substrates, metal and plastic surfaces, this product supports thermal insulation fixing, HVAC insulation bonding, and structural panel assembly in aerospace, transport, and construction sectors. Our range delivers stainless steel insulation bonding pins with precision tolerances to maximize durability and reliability in demanding B2B environments.

Description

Product Features and Technical Specifications – Insulation Pin Types, Materials, Sizes, Tolerances

Insulation Pin Types and Configurations

• CR perforated base plate pins for optimal structural adhesive flow and enhanced bond strength.

• CRY non-perforated base plate pins for clean surface adhesive bonds and specific substrate requirements.

• Choice of standard and custom base plate dimensions to match insulation panel sizes and load distribution needs.

Material Grades and Corrosion Resistance

• Stainless Steel AISI 316 (SS316) insulation pins for superior corrosion resistance in industrial, marine, and chemical environments.

• Optional steel zinc-plated versions for cost-effective projects where corrosion exposure is limited.

• Precision manufacturing ensures tight tolerances for pin diameters and base flatness, critical for consistent bond strength.

Base Plate Sizes and Pin Lengths

• Standard base plate sizes from 15mm round to 58mm square, plus custom sizes on request.

• Pin lengths 50mm–100mm to suit insulation thickness from thin sandwich panels to thicker thermal insulation boards.

• Confirms compatibility with industrial adhesives including epoxy, methacrylate and polyurethane structural adhesives.

Installation Guidance – Surface Prep, Adhesive Selection, Performance

Proper installation of adhesive bonded insulation pins begins with thorough surface preparation: clean, dry, free of dust and grease, and primed where required. Apply industrial structural adhesive uniformly on the base and press the bonding fastener into place, ensuring full adhesive contact with the substrate. Maximum bond strength is typically reached after full adhesive cure (24–48 hours). Choose adhesives that match service temperature ranges, humidity exposure and mechanical load for your application.

Common Industrial Applications – B2B Use Cases

• Thermal insulation fixing on concrete, metal, and sandwich panel structures.

• HVAC system insulation bonding in commercial buildings and industrial facilities.

• Composite and carbon fiber panel assembly in aerospace, rail, and automotive manufacturing.

• Prefab construction elements and modular panel systems requiring non-damage fastening.

Benefits of Choosing Master-Plate® Insulation Bonding Fasteners

• Eliminates mechanical drilling and substrate damage.

• Reduces thermal bridges in insulation systems.

• Highly suitable for structural adhesive applications with defined load and vibration performance.

• Customizable to specific insulation thicknesses and panel geometries for B2B OEM projects.

Download PDF

master_plate_quilting_pins_cr_cry.pdfFrequently asked questions about Insulation pin bonding fastener

How strong is the bond?

Strength depends on the adhesive, the substrate, surface preparation, and bonding area. Correct surface prep is essential and testing is advized. The factory can test if samples are provided in Italy.

Can they handle vibrations?

With the right adhesive applied in the rigth circumstances, bonded fasteners can perform well under vibration loads.

What materials can they be bonded to?

They are typically used on composites, plastics, metal panels, honeycomb structures, carbon fiber, and thin sheet materials.

Which adhesives are recommended?

Usually structural adhesives like epoxy, methacrylate or polyurethane. Give us more info about the application and in cooperation with a adhesive manufacturer, we can provide specific adhesive guidelines.

Are the bonding fasteners always on stock?

For the best-selling items, of course, yes. For the other dimensions, the individual stainless steel components are very often in stock at the factory and only still need to be welded, so you should count on a minimum quantity of 200 pieces and a delivery time of 3 to 4 weeks. For the zinc-plated steel versions, the minimum quantity is 500 pieces due to the galvanizing process, which results in a longer delivery time of 5 to 6 weeks.

When is the non-perforated base plate type interesting?

In general, it can be stated that for medium-sized and large series, the non-perforated bonding fasteners are often more interesting, as on the one hand you save on average 72% of adhesive and on the other hand the quality of the bonded joint is improved.

The bonding quality is then much less dependent on the individual operator.

The shear strength is also higher than with the perforated version.

We recommend checking stock availability, as these items are often not on stock.